Goldstar precision maching equipped with wide variety of precision measuring equipment available for every industrial measuring need. Eevery part is 100% inspected for accuracy. Our quality assurance department is seperated from the manufacturing department, it's the responsibility to support and assist our five plants in defect-free parts.There are 21 stuff in our quality team, Mr Lin is director of QC department, he has over 20years quality managment experience in precision machining parts, he is responsible, patient and detailed-oriented,he makes us work easy.

Quality Policy:

We have various taypes of inspection to assure quality, 1, IN-PROCESS INSPECTION; 2, OUTSIDE PROCESSING; 3,FINAL INSPECTION; 4, DOCK AUDITS

We know that the quality of project is in the entire production process each link work quality synthesis reflected, but is not inspects depending on the pure inspection. Quality rests with each and every employee, each person in this chain must perform his/her duties in a professional and conscientious manner to assure that every product is correct. Goldstar management makes every effort to provide each person with tools and equipment.

Corrective Action C.C.A.R :

Quality control department is the liaison with the cusomter's quality organization; If it is out of specification part was received by the customer, QC will investigate the results and root cause of the defect part, the results of their investigation shall be documented on the C.C.A.R form along with a recommendation of corrective action to prevent reoccureence. The report shall be forwarded to the plant manager for concurrence and then distributed to all of the involved departments for implemention. A written report detailing cause and Corrected Action shall be forwarded to appropriate customer contact. If we make a mistake, we will make it right with you.

With our compliment of precision CNC machining, milling, turning, welding, and grinding, bending, wire EDM, laser cutting, surface finishing, we could be your one- stop shop partner, your satisfaction is our Goldstar precision machining top priority, Let's involved your project early, we will help you spend your money wisely. Contact us today!

Quality Assurance Equipment List

CMM

CMM  Raw Materal Tester(BRUKER Brand)

Raw Materal Tester(BRUKER Brand)  Electronic depth micrometer

Electronic depth micrometer

Hight Micrometer

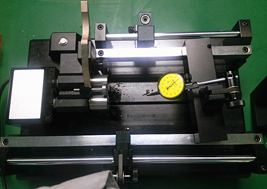

Hight Micrometer  Centralized measuring equipment

Centralized measuring equipment  Electronic indicator

Electronic indicator

Electronic I.D. Capliper

Electronic I.D. Capliper  O.D Micrometer Caliper

O.D Micrometer Caliper  Rockwell hardness tester

Rockwell hardness tester

Stereomicroscope

Stereomicroscope  Electronic depth micrometer

Electronic depth micrometer  Flatness gage

Flatness gage

Digital force gauge

Digital force gauge  Ring thread gauge

Ring thread gauge  Standard plug gauge

Standard plug gauge

Micro-image measurer

Micro-image measurer  Hight Micrometer

Hight Micrometer  Plug screw gauge

Plug screw gauge

Caliper

Caliper  Blade type calipe

Blade type calipe  Surface roughness measuring device

Surface roughness measuring device

Leeb hardness tester

Leeb hardness tester  Bore gages

Bore gages

QC on spot training Waiting inspeciton area Production schedule Kan Ban